Talga Resources’ graphite anode material beats ‘leading’ anode product in lithium-ion battery tests

Full scale pouch cells targeting 4Ah capacity containing Talga Resources’ graphite anode and NMC cathode.

Testing on Talga Resources’ (ASX: TLG) graphite anode material in lithium-ion batteries has come up trumps against the current leading anode graphite.

Part of the University of Warwick, independent testing facility WMG carried out the battery assessments on Talga’s graphite in commercial sized lithium-ion batteries and compared it to anode material currently used in commercial batteries.

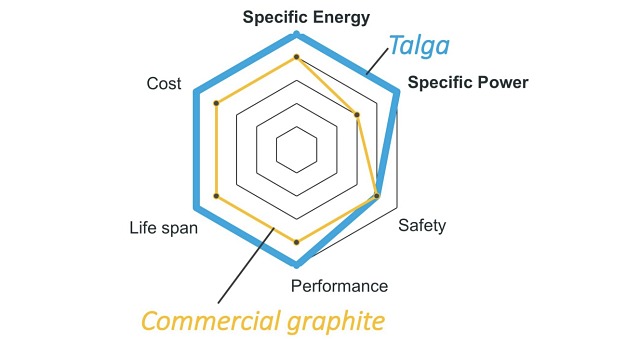

The results revealed Talga’s graphite had 20% more capacity and power, 94% first cycle efficiency and no capacity fade after 300 cycles.

“These results are a highly significant development for Talga,” Talga managing director Mark Thompson said.

“The unique characteristics of our Swedish graphite ore body, combined with our proprietary processing technologies produces a lithium-ion battery with significantly higher power and energy as tested by WMG,” he said.

Additional efficiencies in Talga’s graphite anode material included reduced processing costs because there was no need for micronisation, spheronisation and coating. As a result of less downstream processing requirements there was a smaller amount of waste, energy consumption and associated environmental impacts.

“We also don’t see their large milling losses resulting from milling down large graphite flakes to suit battery anode size material,” Mr Thompson said.

“Talga’s significant resources positions our energy products division to evolve into a stand-alone battery technology company with exclusive access to a lower cost and unique, high performance battery-grade graphite, sourced from our wholly-owned deposits in Sweden,” he added.

Talga’s graphite/graphene strategy

Talga wholly-owns its graphite deposits in Sweden, which it claims host the largest resources in Europe.

As part of it its plan to become a vertically integrated miner, processer and supplier, Talga holds a 100% interest in graphite and graphene processing facility in Germany, based on its proprietary technology.

The company’s technology can produce graphene and nanographite products for lithium-ion batteries, coatings, construction and composite sectors.

Using its graphite and proprietary technology, Talga claims it can entered the market at a higher level of the lithium-ion anode supply chain and command a higher price.

The company is currently in talks with battery manufacturers and end-users based in Asia and Europe.

Talga is also progressing its product development with a marketing team installed in the UK. The company also appointed a senior battery scientist Dr Fengming Liu to its UK team at the beginning of the month.

Talga’s share price closed yesterday at A$0.73.