The June quarter saw Lithium Universe (ASX: LU7) redirect its energy to solar panel recycling, specifically the acquisition of cutting-edge technology which capitalises on critical metals content of photovoltaic (PV) cells.

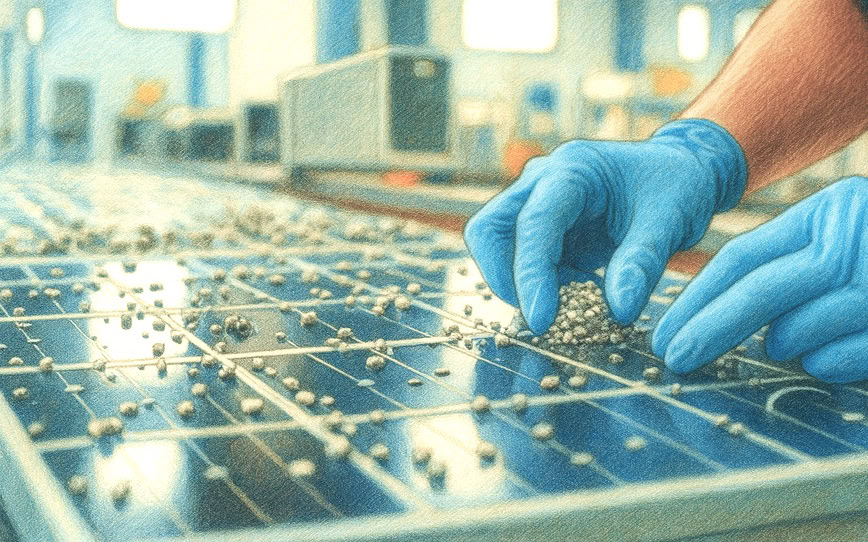

Lithium Universe acquired the global rights to microwave joule heating technology developed by Macquarie University, which aims for higher recoveries of critical minerals by utilising microwaves to selectively heat and delaminate PV cells.

The company hopes the process will combat global solar cell waste statistics, which estimates up to 78 million tonnes of spent modules will be accumulated in landfill by 2050.

Solar Panel Waste

Australia is expected to accumulate 1Mt of solar panel waste worth more than $1 billion by 2035, and will need to recycle or repurpose an estimated 34.6 gigwatts of serviceable panels by 2045.

Research has demonstrated that up to 98% of silver and nearly all of copper, lead and other valuable metals can be recovered efficiently from PV cells, enhancing the profitability of the recycling industry.

New technologies such as microwave joule heating could potentially play a crucial role in supporting the transition to a circular economy and sustainable energy future.

Critical Minerals Supply

Executive chair Iggy Tan said that the potential to unlock a new source of silver, silicon, gallium and indium to feed the high-tech industry as the focus on critical minerals supply continues to intensify has a lot of value.

“It aligns well with our strategy of developing mineral processing technology and infrastructure for the circular economy and will see us well-positioned for when the market rebounds.”

“Waste PV cells that end up in landfill contain harmful materials like cadmium and lead which can leak into the ground and pose risks to ecosystems and human health [and] the valuable metals are also lost, adding to the strain on natural resources.”

“Microwave technology offers a promising solution to these challenges, enabling higher recovery rates and more sustainable recycling processes,” he added.

Silver Recovery

With silver prices riding high, Mr Tan said the company would focus Phase One of its recycling plan on the recovery of around 20 grams (or 0.7 ounces) of the base metal from each cell (worth around $36 at current prices).

“Waste management is a growing concern globally and with only 15% of panels currently being recycled, the need for an effective process has never been greater,” he said.

Analysts project the value of critical minerals in these panels to be approximately $80 billion.

Bécancour Refinery Talks

Lithium Universe is in talks with potential offtake partners and spodumene concentrate producers after a definitive feasibility study confirmed the viability of its planned Bécancour lithium carbonate refinery in Canada, even in a below-average pricing environment.

Mr Tan said securing long-term local feedstock would be key to unlocking the next stage of funding.

“In our discussions with spodumene concentrate producers, they have all acknowledged the benefit of supplying their product to a local lithium converter as opposed to shipping to Chinese operations for conversion,” he said.

“Spodumene transport costs to China could be as high as US$100 per dry metric tonne and shipping the final lithium carbonate back to North America could add another US$200 per tonne plus the 25% Canadian import tariff — all of these factors give local conversion an over-riding price advantage.”

Lithium Universe is also engaging with financial institutions and government agencies to secure financing for the Bécancour project.