Lithium Australia advances LieNA sustainable spodumene processing technology

Lithium Australia’s LieNA technology can process lithium-rich spodumene particles that are usually expelled to waste.

Lithium Australia (ASX: LIT) has started a preliminary feasibility study for its LieNA spodumene processing technology, which doesn’t use conventional high-temperature methods and isn’t constrained by particle size.

The company has refined the process in collaboration with the Australian Nuclear Science and Technology Organisation (ANSTO).

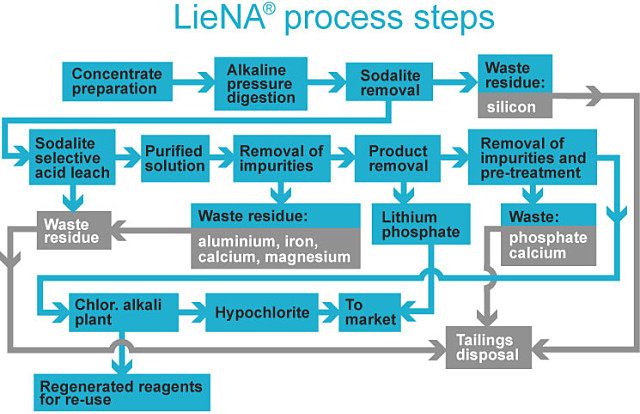

Instead of using high-temperatures, LieNA works with an alkaline source such as caustic soda to convert spodumene into a lithium-bearing sodalite.

In the next step, the sodalite is recovered then leached to generate a lithium-bearing solution. This solution is then treated to produce a high-purity refined tri-lithium phosphate product.

LieNA can process waste

According to Lithium Australia’s managing director Adrian Griffin, the LieNA process provides a number of advantages over conventional spodumene methods including the ability to process fine spodumene feedstock which is usually left as waste.

“The production of lithium concentrates from spodumene results in the generation of a large amount of fine spodumene that cannot be used as feed for conventional lithium convertors (factories that produce lithium chemicals from spodumene),” Mr Griffin explained.

“In fact, the fine material discharged as waste during the concentration process may contain up to 50% of the lithium value.”

He pointed out that Lithium Australia’s LieNA technology could provide a sustainable processing solution with its ability to recover lithium from fine spodumene waste.

Other LieNA benefits

Other advantages with LieNA include generating high-purity battery chemicals without producing sodium sulphate as a by-product, which is what happens during conventional thermal processing.

Additionally, LieNA enables a suite of lithium chemicals to be produced from a single refinery including lithium phosphate, hydroxide, sulphate or chloride.

“Not only does the LieNA technology provide greater sustainability but it can also supply direct feed for the production of lithium-ferro-phosphate cathode materials, a chemistry ideally suited to energy storage applications,” Mr Griffin added.

As part of the company’s intellectual property protection strategies, Lithium Australia has lodged patent and patent cooperation treaty applications for LieNA.