Leigh Creek Energy edges closer to commercial syngas flows

The Leigh Creek energy project pre commercial demonstration plant gasifier is currently in pyrolysis, which is the final phase before commercial syngas flow.

Emerging gas developer Leigh Creek Energy (ASX: LCK) is on the verge of achieving commercial flow rates of synthesis gas from its namesake energy project in South Australia.

The company today announced gas has been flowing continuously from its pre-commercial demonstration facility for the past 53 days and is anticipating reaching the commercial gas phase by the end of December.

This progress brings Leigh Creek Energy closer to its near-term goal of upgrading its 2964-petajoule 2C resource to proven and probable reserve status, which it expects will add significant value to the company.

The syngas process

Leigh Creek Energy’s pre-commercial demonstration facility generates synthesis gas, or ‘syngas’, via in situ gasification (ISG), which is a chemical process used to convert coal from a solid state into a gaseous form, under heat and pressure.

While syngas can be used for various purposes including to produce electricity or natural gas directly, the company announced last month it had selected fertiliser production as the commercial pathway for its project, located at the Leigh Creek coalfields in northern SA.

Leigh Creek Energy initiated the gasifier at the facility in early October, with the gradual process for the gasifier to develop through to full syngas production typically expected to take a period of weeks.

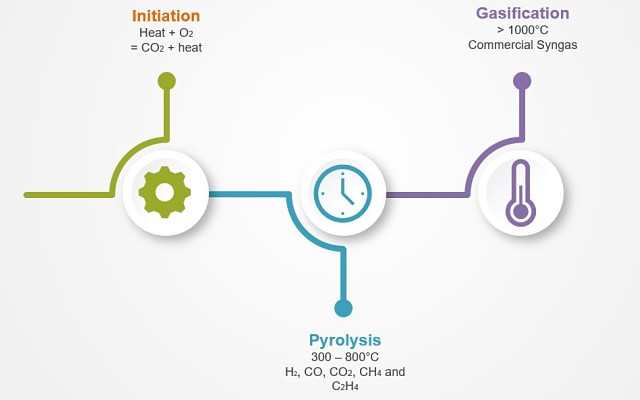

After ISG initiation, deep coal combusts and gradually enlarges a gasification chamber, producing carbon dioxide. This is stage one of the process, called combustion.

As the chamber develops with increased heat (in the range of 300 to 800 degrees Celsius), the second stage progresses, and the combustion chemical reactions of coal change to pyrolysis, producing a different combination of gases.

The Leigh Creek pre-commercial demonstration is currently in this pyrolysis stage.

As the gasification chamber continues to increase in both size and temperature, very hot gases (typically at temperatures above 1000 degrees Celsius) interact with the coal to form syngas.

This is the commercial gas phase, which the company expects to be in by the end of the 2018 calendar year.

Leigh Creek Energy managing director Phil Staveley said the pre-commercial demonstration was developing “as expected, both technically and operationally”.

“LCK’s on-site operations team and Adelaide-based technical experts continue to manage the development of the PCD gasification chamber toward commercial flow rates, by managing the gasifier’s operating parameters, such as pressure, water inflow and outflow rates,” he said.

Mr Staveley added that “no environmental impacts” had been detected by the company’s “extensive monitoring regime” as it continued to work closely with the regulator to ensure appropriate oversight.

Resource upgrade

Once commercial syngas flows have been achieved, the company will begin the process of upgrading the current 2C resource of its Leigh Creek project.

It is aiming to convert a portion of this 2964PJ resource into proven and probable reserves and hopes to achieve this status during the first quarter of 2019.

“We are now entering a very exciting and potentially very commercially significant phase of the development of our major asset at Leigh Creek,” Leigh Creek Energy stated in its announcement to the market.

“This re-valuation of the company’s major asset will add significant value to the company’s balance sheet and should reflect in its near-term share price,” it said.