Kibaran moves a step closer to supplying the EV market with graphite

Kibaran Resources (ASX: KNL) has completed significant testwork on its battery (spherical) graphite, which was produced using Epanko graphite, at a leading lithium-ion battery facility in Germany.

Key Highlights:

- Successful production of battery anode material using Epanko battery (spherical) graphite.

- Electrochemical testing and benchmarking of lithium-ion battery anode cells using Epanko anode slurry completed with results exceeding expectations.

- Positive feedback from leading industry groups has led to larger quantities being requested, the prerequisite for securing commercial sales for battery (spherical) graphite.

- All testwork was undertaken at industrial scale production plants to replicate commercial production.

The performance of the lithium-ion battery anode cell using slurry produced from the Epanko battery (spherical) graphite is a significant achievement and confirms the quality and suitability of Epanko graphite for the production of anode material for lithium-ion batteries.

The testwork is part of Kibaran’s current feasibility study on the production of battery (spherical) graphite which is due to be completed Q3 2017.

Benchmarking of Epanko anode slurry in lithium-ion battery anode cells

The Epanko battery (spherical) graphite was compared with a commercially available product used in anode production to benchmark its performance. Both samples were uncoated spherical graphite with the test focused on the performance of uncoated spherical graphite.

A leading German group executed the electrochemical testwork, which aimed to supply reliable data on the real life performance of the Epanko battery (spherical) graphite. Therefore no additional carbon (such as carbon black) was used to increase conductivity and higher capacity rates, as carbon black contributes to the storage of lithium-ions on the anode side.

Figure 1: Example of a lithium-ion battery showing anode cell with graphite slurry pasted onto the copper foil.

The anode slurry was prepared using 92.5% Epanko battery (spherical) graphite and 7.5% binder. The slurry was coated on copper foil (refer Figures 1 and 2). The lithium-ion battery was filled with standard electrolyte.

It’s important to note that the tests were not designed to achieve the highest values, which can be manipulated by changing the various test parameters (such as adding carbon black or higher concentrations of electrolyte) but were designed to achieve a realistic performance comparison to commercially used reference material for the benefit of customers.

Figure 2: Energy-dispersive X-ray spectroscopy (EDX) cross section through the anode cell showing Epanko battery (spherical) graphite coated on to the anode copper foil.

Rate capability tests were undertaken to analyse the behaviour of the lithium-ion battery across a range of different charge (C-rate) and discharge (D-rate) conditions.

The tests revealed very good reversible capacity (~360mAh/g) when cycled with low C-rates and when higher C-rates were applied, the capacity dropped in a consistent manner to the reference material. Encouragingly, when lower C-rates were re-applied, the capacity of the Epanko (spherical) graphite lithium-ion battery went back to higher levels than the reference material, demonstrating the superior performance and characteristics of the Epanko slurry material. After 52 cycles with variable and in some cases extreme charge and discharge parameters (5C-rate and 5D-rate respectively), the Epanko (spherical) graphite lithium-ion battery still produced a reversible capacity at 0.2C of 324mAh/g, compared to just 307mAh/g using the commercially used reference material.

Figure 3: Charge/Discharge behaviour at 0.2C of Epanko (spherical) graphite lithium-ion battery (left) and commercial reference material (right).

C-rate is a measure of the rate at which a battery is charged relative to its maximum capacity. A 1C rate means that the charge current will charge the entire battery in 1 hour (60 minutes), 0.2C means complete charging is made during 5 hours (60minutes/0.2 = 5 hours) and 5C means that complete charging was made in 12 minutes (60 minutes/5 = 12 minutes).

Importantly, a 10 cycle test showed that the reversible capacity of the Epanko (spherical) graphite lithium-ion battery material at 0.2C was higher than the commercial reference material.

Advanced testwork progressing with leading industry groups

Following the positive initial tests confirming the high performance of the Epanko battery (spherical) graphite, various leading industrial anode material producers have ordered larger quantities of Kibaran’s graphite products and are currently conducting further advanced testwork and analysis.

Based on their feedback Kibaran will be able to customise its Epanko battery (spherical) graphite products to individual customers’ specific requirements. This work is being progressed in conjunction with a request from the Kibaran’s partner Sojitz Corporation of Japan for product samples to meet detailed specifications for leading anode manufacturers.

Forecast demand for spherical graphite in lithium-ion batteries for EV market

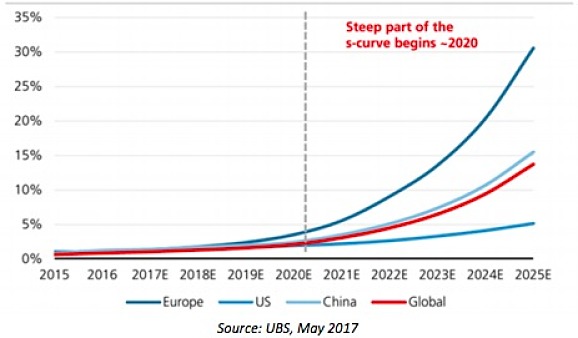

The strong demand growth for high quality graphite products will be primarily driven by the increasing focus on global climate change policy and energy efficiency initiatives, currently reflected in the exponential growth forecast in the sale of Electric Vehicles (‘EV’).

Figure 4: Forecast global EV penetration rates by region.

In recent weeks both France and the United Kingdom have joined India and Norway in banning the future sale of diesel and petrol vehicles. Across Europe, Germany, Denmark, Austria, Spain, The Netherlands and Portugal have all set EV targets, while in Asia, China (which accounts for 40% of global vehicle sales), Korea and Japan have also adopted similar policies.

The interest in the Epanko battery (spherical) graphite has significantly increased since Kibaran commenced its feasibility study and the additional German support aligns the company with Europe’s expanding role in the development of new electric vehicle technologies.

This is expected to ultimately position Kibaran as a key participant across the value chain of the high growth global lithium-ion battery industry.

Figure 5: Kibaran participation in the global electric vehicle market.