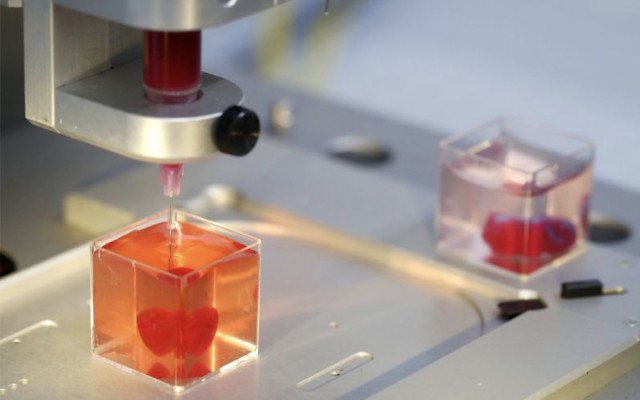

Israeli researchers create world’s first 3D printed heart with human tissue

Scientists and researchers have 3D printed the world’s first human heart, with the hope it will become transplantable into heart disease patients within a decade.

Scientists at Tel Aviv University (TAU) in Israel have manufactured a 3D printed heart made from organic tissue of the patient – a direct improvement on existing synthetic or artificial versions that are often rejected by the recipient’s immune system.

The breakthrough has been hailed as a potentially revolutionary technology that could make organ donations redundant over the next decade, according to the team behind the technology.

The team of researchers led by Professor Tal Dvir, Dr Assaf Shapira and Nadav Noor from TAU’s School of Molecular Cell Biology in combination with its Faculty of Life Sciences department have created the world’s first printable 3D heart – complete with blood vessels made from personalised “ink” made from collagen, a protein that supports cell structures and facilitates the creation of other biological molecules.

Professor Dvir called his team’s development a “major medical breakthrough” that advances possibilities for transplants with a realistic chance of making organ donations obsolete at some stage in the future. Although by his own admission, it will be several years before doctors can expect the technology to be offered to humans.

“This is the first time anyone anywhere has successfully engineered and printed an entire heart replete with cells, blood vessels, ventricles and chambers,” said Mr Dvir.

The 3D heart produced at TAU was on a small scale and designed to fit a rabbit, but the professor said that larger human hearts could be produced using the same technology following this proof of concept.

“This heart is made from human cells and patient-specific biological materials. In our process, these materials serve as the bioinks, substances made of sugars and proteins that can be used for 3D printing of complex tissue models,” said Professor Dvir.

The heart is too small for human use, but the process shows the potential to one day being able to 3D print patches and possibly full transplants.

He added that “our results demonstrate the potential of our approach for engineering personalised tissue and organ replacement in the future.”

One of the challenges now overcome is the aspect of immune response and donors rejecting organs due to incompatible tissues. Using the patient’s own tissue is important in eliminating the risk of an implant provoking an immune response and being rejected, according to Professor Dvir.

Healing broken hearts

Cardiovascular diseases are currently the leading cause of death in industrialised nations. In the US, heart disease is the leading cause of death among both men and women with heart transplants becoming ever-more common.

However, waiting lists for patients are around six months or more with most countries unable to offer patients heart transplants at all. In Australia, around 70 people receive a heart transplant a year.

To date, heart transplant is the only treatment for patients with end‐stage heart failure with scientists across the world desperate to find solutions to this growing problem.

Since the number of cardiac donors is limited while the amount of organ recipients is growing, there is a dire need for a new approach to assist millions of people that need a new heart.

If successful, the technology developed at TAU could enable the manufacture of other organs in a similar methodology given that the heart is one of the most complicated to reproduce.

The same issue also occurs for all other organs. According to the American Transplant Foundation, around 114,000 people are currently on the waiting list for a lifesaving organ transplant in the US with around 20 people dying every day due to a lack of available organs.

Challenging times ahead

Despite the achievement and the plaudits received by the team at TAU, the scientists said many challenges remain before fully working 3D printed hearts will be available for transplant into patients.

Tempering the excitement behind the achievement, the researchers said that their 3D printed heart was still some way short of being a fully-functional heart that works in practice. At this stage, their achievement has been described as a “proof of concept” with animal trials seen as the next step to test the technology.

Until now, scientists have been able to create simple biological tissue such as cartilage, valves and other tissues but the holy grail has been to create tissues complete with vascularisation. In other words, organic tissue complete with blood vessels and capillaries – aspects without which organs cannot function properly.

In its research published by Advanced Science, the TAU team said that it demonstrated the ability to grow tissue by using a patient’s existing cells and was able to improve blood vessel architecture by using “mathematical modelling of oxygen transfer”.

The authors said that organ printing involves three key stages.

The first step is to scan the organ with existing technology such as a magnetic resonance imaging (MRI) machine.

Stage two is printing the organ, layer by layer, and the third stage involves “maturing” the printed organ in an appropriate environment.

Professor Dvir also explained that multiple challenges still remain including how to expand the cells to have enough tissue to recreate a human-sized heart and how to overcome the existing low resolution of 3D printers.