International Graphite (ASX: IG6) has received the nod of approval from Western Australia’s state government to install graphite micronising equipment at its downstream research and development facility in Collie.

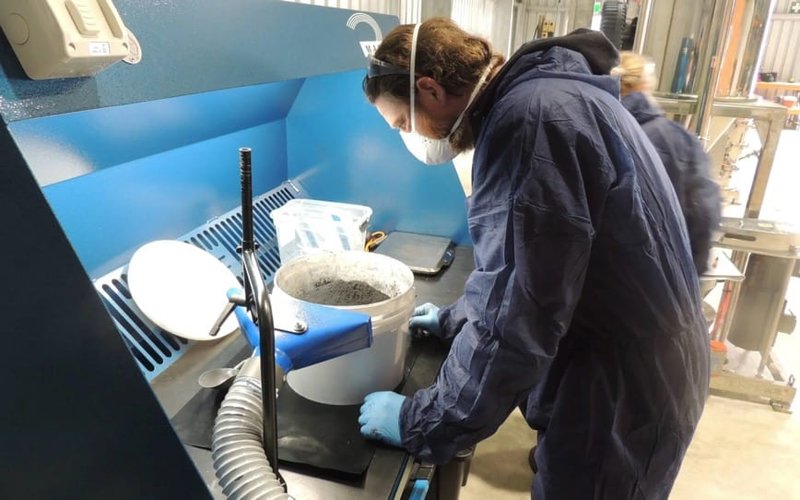

The custom-built “qualification-scale” plant is designed to process graphite concentrates to produce a commercial micronised graphite product for quality and performance evaluation by potential customers.

It is capable of outputting up to 200 tonnes per annum of micronised graphite and will also be used to further develop the company’s graphite operating and materials handling expertise.

In March, International Graphite released a definitive feasibility study for the $12.5 million facility with a nominal capacity of 4000tpa.

It is expected to be operational in late 2024.

Significant advancement

The new plant is considered to be a significant advancement on International Graphite’s pilot processing plant which was commissioned in late-2022 as an Australian first.

It will also be available to progress testwork on concentrates from the company’s wholly-owned Springdale graphite project on WA’s south coast and will assist with research, development and market qualification of graphite material.

Equipment for the plant is in transit from North America and is expected to arrive at Fremantle Port next month.

Mine-to-market producer

Chief executive officer Andrew Worland said a micronising operation would progress International Graphite’s plans to be WA’s first mine-to-market producer of graphite battery anode materials for the growing lithium-ion battery market.

“Micronised graphite is a by-product of the micronising and spheroidising process used in the production of battery anode materials and contributes to the economics of production,” he said.

“A commercial-scale micronising facility would help establish markets for future micronised by-products that would be produced in Collie.”

Infill assays

Earlier this month, International Graphite reported “sensational” assays from infill and exploration drilling at Springdale’s new Mason Bay target.

Best results were 11 metres at 11.7% total graphitic content (TGC) from 47m and including 2m at 21.9% TGC; 13m at 6.4% TGC; 14m at 7.8% TGC; and 12m at 11.6% TGC.

Other assays from the same campaign were 3m at 19.1% TGC including 2m at 27.5% TGC; 15m at 12.4% TGC including 5m at 29% TGC; and 10m at 6.7% TGC with a 1m interval returning 21.2% TGC.

Mr Worland said the results from Springdale were “clear evidence of the enormous graphite potential”.