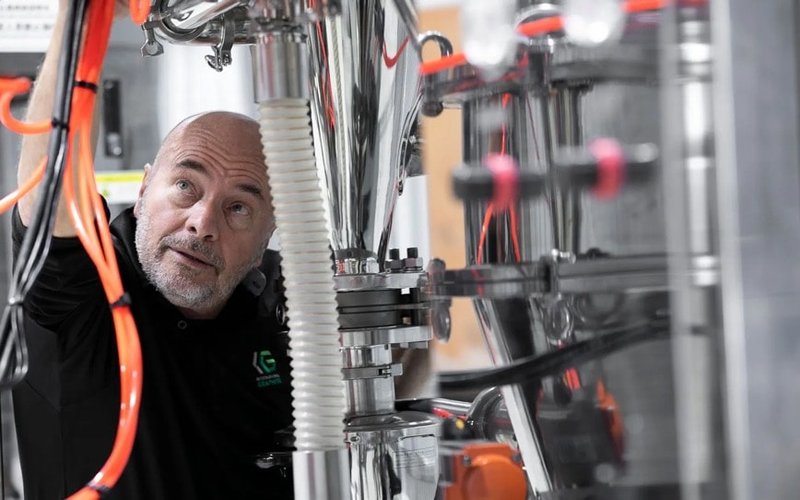

In another key milestone in its dual-threat battery metals strategy, Western Australia-based International Graphite (ASX: IG6) has successfully commissioned its new graphite micronising plant at Collie, south of Perth.

The 200 tonnes per annum qualification-scale microniser will be the first to produce graphite products in Australia for customer acceptance testing.

It has been developed as the pilot plant ahead of the construction of a 4,000 tpa commercial micronising facility the company is aiming to have operating at Collie within 18 months.

The company says construction of the approximately $12.5 million plant could be given the green light as early as mid-year.

International Graphite selected the micronising path to enable it to initially develop a customer base, gain operating experience, build markets for future by-products and generate cashflow.

Springdale integration

Notably, the feed material for the trial and full-scale micronising plants will be supplied by International’s Graphite’s 100%-owned Springdale graphite project on the south-east coast of WA.

Located near the town of Hopetoun, Springdale is the largest undeveloped graphite resource in Australia and a significant component in International Graphite’s integrated development plan.

A recently-completed scoping study successfully highlighted the benefits of that integrated development strategy.

The study focused on a mine-to-market operation and confirmed a globally competitive cost structure with a multi-decade operating life.

It also confirmed robust project economics with significant potential for expansion at the Springdale and Collie operations.

The company is now targeting the completion of a definitive feasibility study by the end of calendar year 2024.

First of its kind

Managing director and chief executive officer Andrew Worland said a fully-integrated graphite supply from WA will be one of the first of its kind in the western world.

The plan has already attracted the attention of potential customers and finance partners in Australia, Japan, Korea and North America.

“We see breaking into the micronised graphite market as an important step in developing our Springdale-Collie mine-to-market strategy,” Mr Worland said.

“Demand for batteries will continue to grow. There are already more than 240 battery gigafactories operating worldwide and up to 400 expected to open by 2030. All of them will need a secure source of graphite materials.”

“Australian companies like us are in the box seat to deliver. We have the assets, the technical capability and WA has an unparalleled reputation as a top resource supplier with outstanding ESG [environmental, social and governance] credentials.”

WA government support

International Graphite’s plans to create a new critical minerals business in regional WA has been welcomed by the state and federal governments, which have contributed a combined $6.7m in grant funding towards the project.

More than 100 jobs are expected to be created at Springdale and Collie.

Micronised graphite is used in many industrial products and, along with being a critical conductive additive in the cathode of lithium-ion batteries, is also the first stage in producing graphite anode material for battery-powered technologies, particularly electric vehicles and green energy storage.

A lithium-ion battery can use up to 10 times more graphite than lithium.

The battery in a standard electric car requires about 75 kilograms of graphite (approximately 1kg for every kilowatt-hour of power capacity).

China currently produces around 90% of the world’s processed graphite.

However, it introduced export restrictions in December, adding further pressure to future supply.