Frontier Energy confirms green hydrogen production technology for Bristol Springs solar project

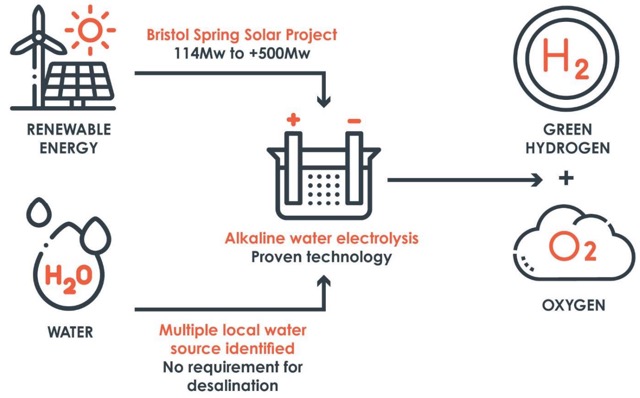

Frontier Energy intends to use alkaline water electrolysis technology to produce green hydrogen at its WA solar project.

Aspiring clean energy producer Frontier Energy (ASX: FHE) has announced alkaline water electrolysis as its preferred technology to produce green hydrogen at the Bristol Springs solar project in Western Australia.

The technology was chosen due to its lower cost and “technical robustness” compared to other currently available methods, the company said. Another advantage is the modular nature of its installation, which allows for hydrogen production earlier than originally anticipated and for staged future expansion.

Frontier also announced the signing of a memorandum of understanding (MoU) with leading hydrogen industry experts, Oslo-listed Nel Hydrogen and Australian business ENGV, to assist in the development of the production plant and market distribution.

Frontier managing director Mike Young says the accelerated development of the Bristol Springs project will also fast-track the evolution of the green hydrogen industry, which is already approaching parity on cost with diesel powered haulage systems.

“We aim to become one of the first commercial green hydrogen producers in Australia,” he said.

“The MoU with Nel and ENGV ensures that our green hydrogen strategy is carried out in the most efficient manner,” Mr Young added.

Nel and ENGV to assist in hydrogen study

Under the terms of the MoU, Nel and ENGV will assist with the advancement of Frontier’s hydrogen study including furthering the development of the green hydrogen production plant, compression and storage, and distributing to market.

Nel is expected to provide the hydrogen technology solutions while ENGV will provide integration services.

Frontier today confirmed it remains on track to release both the renewable expansion and the complete green hydrogen study by mid-year.

This latest news follows Frontier’s announcement earlier this month that it had identified numerous water sources near its Bristol Springs project which means “major cost savings” for the company.

Alkaline water electrolyser technology

The process of ‘electrolysis’ effectively uses electricity to split water into hydrogen and oxygen gases. ‘Green’ hydrogen is produced when this electricity is supplied through renewable sources such as solar, wind and hydro.

Hydrogen production flow sheet.

As part of Frontier’s plan to produce green hydrogen, several electrolyser technologies were assessed to determine the most appropriate plant design.

In addition to alkaline water electrolyser, these were proton exchange membrane, solid oxide, anion exchange membrane, and capillary-fed electrolysers.

According to the company, alkaline water electrolyser technology was found to offer the lowest cost per kilowatt of installed capacity, in addition to long-term operational stability and plant life.