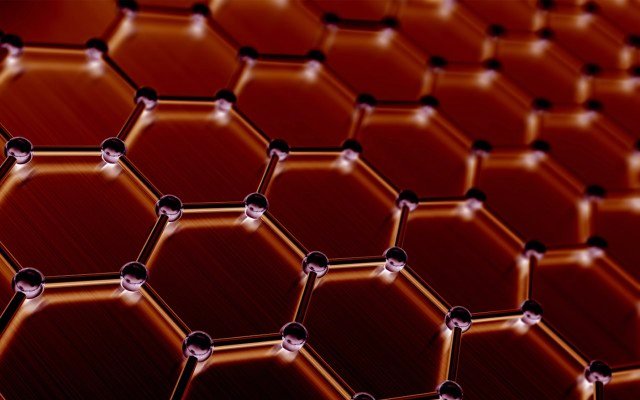

In its latest achievement, First Graphene (ASX: FGR) has revealed its PureGRAPH graphene product boosts the safety of polyurethane material when added by improving its fire retardancy.

According to the company, several institutions have undertaken research and found that adding graphene to polyurethane elastomers provides “very useful fire retardancy qualities” in addition to other benefits.

The University of Adelaide and First Graphene have been carrying out tests on the performance of the PureGRAPH product range when added to polymer compounds, with initial results proving “impressive”.

During testing, base polyurethane elastomer burned with a limiting oxygen index (LOI) of 22.85%. When 1% of PureGRAPH was added to the polyurethane material, the LOI was raised to 31.6%.

Under normal atmospheric conditions this means the PureGRAPH-enhance polyurethane material does not propagate or support flame and will only burn in the presence of significantly higher oxygen levels.

“Fire in rubbers and polyurethane elastomers costs the mining industry considerable amounts, both in terms of replacement and foregone productivity,” First Graphene managing director Craig McGuckin said.

“Using PureGRAPH to both increase the time between replacement and limit fire provides a considerable benefit to the users of polyurethane elastomers.”

“Further tests will be conducted, but certainly these initial results are very encouraging,” Mr McGuckin added.

As well as fire retardancy, previous tests have demonstrated PureGRAPH products also afford “significantly increased” tension, tear, and abrasion wear characteristics when included in polyurethane material.

First Graphene expects these characteristics and the enhanced fire retardancy make its PureGRAPH product appealing to the mining industry.

NICNAS approval

Today’s news follows First Graphene’s report it had received National Industrial Chemicals Notification and Assessment Scheme (NICNAS) approval from the Western Australian Government.

The approval paves the way for First Graphene to produce and sell its PureGRAPH products within Australia, with the products to be produced at First Graphene’s 100 tonnes per annum facility in WA.

NICNAS approval combined with REACH registration places First Graphene as the only entity in the world permitted to sell up to 10tpa of graphene powders into the UK and Europe as well as its products throughout Australia.

“This completes the approval of our graphene materials in Australia,” Mr McGuckin said.

“In conjunction with First Graphene’s REACH registration it demonstrates our position as the leading ethical supplier of tonnage quantities of high-quality graphene products,” he added.

Prior to market open, First Graphene’s share price was at $0.31.