First Graphene (ASX: FGR) has reported the addition of graphene to perovskite solar cells (PSC) can almost double efficiency to 30% and reduce production costs by up to 80%.

The company has partnered with Halocell Energy and Queensland University of Technology to develop graphene-enhanced PSCs through the addition of its PureGRAPH novel functionalised graphene.

A three-year $2.03 million grant under the federal government’s Co-operative Research Centres Projects (CRC-P) program is funding the research and development agreement, which commenced in 2023.

R2R-Compatible Product

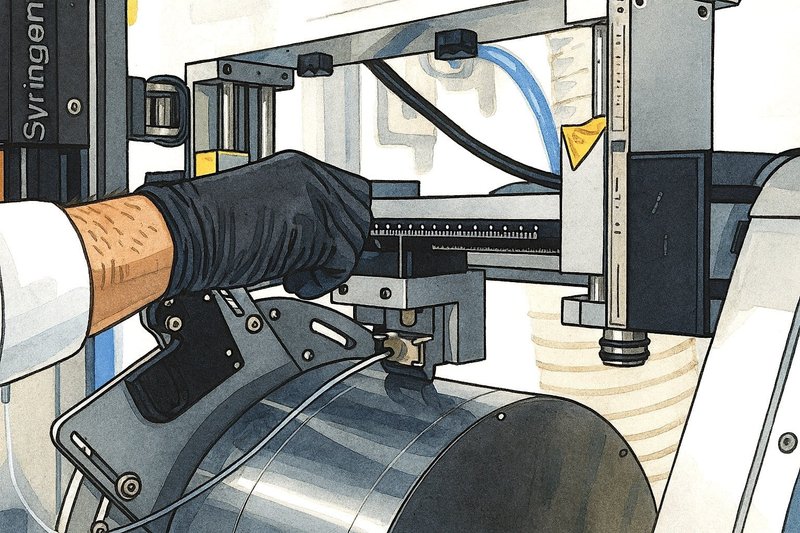

PureGRAPH is compatible with roll-to-roll (R2R) dispersion technology, which eliminates traditional high conductor and high-cost materials such as gold and silver from PSCs.

R2R is the cheapest PSC manufacturing method, introducing cost and volume efficiencies which give Halocell’s cells a market advantage against competitors.

Photovoltaic cells made with alternative carbon-based materials such as graphene have been shown to outperform conventional silicon cells in low and artificial light conditions including indoor environments, generating and supplying power for niche applications.

Perovskites can provide lower manufacturing, processing and energy costs and their energy payback period can be as low as six weeks compared to silicon cells which take approximately two years.

High-Performance Coating

First Graphene entered a two-year commercial agreement in September to supply Halocell with PureGRAPH for use as a high-performance coating in its cells.

Halocell has been selling indoor, low-light PSCs – mainly for use in small electronic items – to the Australian market since then.

Many consider PSCs the best solution to replace the hundreds of millions of batteries used in small electronic devices such as TV remotes, calculators, toys, lights and torches, e-readers and tracking devices.

They also have applications in high-end devices such as satellite solar modules, fixed wing drones, shark detectors, biomedical sensors and weather stations.

Australian Innovation

First Graphene managing director Michael Bell said the company was pleased with the progress that Halocell was making in applying PureGRAPH to PSC development.

“Halocell’s ambient module product line has been commercially available since September, meaning our partnership is generating competitive Australian innovation with global reach,” he said.

“Production of these cells fits with our decarbonisation mantra when applying graphene to materials, which is proven to improve product performance, extend life and dramatically lower production costs to create a highly-competitive product available to market.”

Halocell has identified 44 devices across the IoT (Internet of Things), electronics, space, aviation and full sun sectors that could potentially benefit from PSC technology, and is in the process of seeking capital to expand the capacity of its New South Wales plant through modular expansion of R2R production lines and boosting operating capability, targeting the annual manufacture of as many as 60 million PSC units.