Perth-based company Aurora Labs (ASX: A3D) has reported significant progress in an intensive research and development program focused on its patented multilayered concurrent printing (MCP) technology.

Increased interest in 3D printing from global manufacturers has seen the company move its attention to the MCP prototyping stage to demonstrate its capabilities and provide a platform for commercial discussions.

It has proposed further research projects for the development of computer-based simulations to explore varied configurations of MCP in new machine designs.

Disruptive change

Aurora’s MCP technology is potentially a disruptive change to the 3D printing market as it breaks the process of single layer printing.

Instead of printing on one plane or layer at a time like most other 3D metal printers on the market, Aurora’s MCP can print on multiple layers concurrently.

This increases production speed and allows more material to be melted in an efficient timeframe.

The company said it would work on a seamless integration of new product developments which incorporate a step change in the printing process through the utilisation of MCP technology.

Immediate pathway

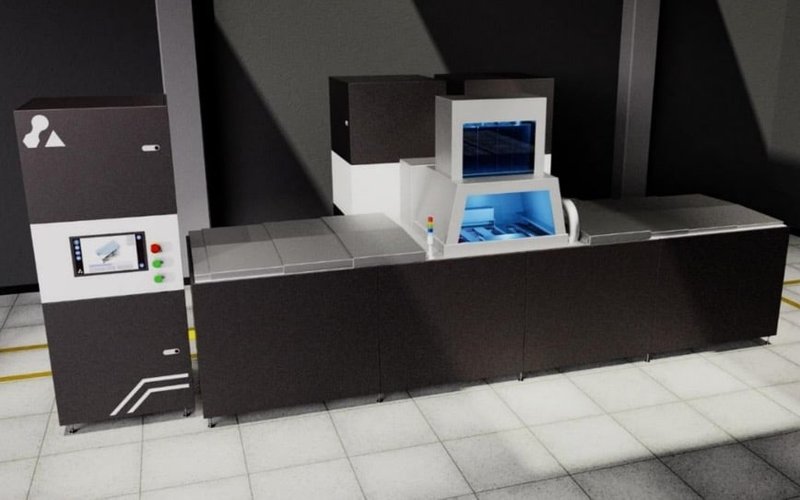

Aurora’s recently-launched AL250 machine has presented the company with an immediate pathway to furthering its 3D printing research.

The printer’s advanced design offers a bi-directional recoating of powders integrated with its MCP technology.

Once completed, the design is expected to be bolstered by further computer simulations and innovations as new prototypes are delivered in 2024.

Prototype efficiencies

Chief executive officer Rebekah Letheby said the prototypes would focus on efficiencies of machine costs by reducing the number of complex laser systems; maximising laser melting of material; and maximising printer bed size while exploiting the MCP patent by designing new recoating systems.

“MCP has challenged industry perceptions that laser powder bed fusion is slow and expensive… [we are focused on a] potential marked increase in throughput, ultimately outpacing the speed of existing single layer printing methods,” she said.

“We have a great deal of work to do throughout this project to deliver, but we look forward to the challenge.”

Ms Letheby said Aurora had commenced discussions with industry and academia groups with a view to forming partnerships and collaborations to address engineering challenges associated with the AL250 project.