Sparc Technologies (ASX: SPN) has partnered with the Australian Institute for Machine Learning (AIML) at Adelaide University to co-develop AI software aimed at modernising protective coatings performance assessment.

The project focuses on applying computer vision and machine learning to improve the efficiency, accuracy, and consistency of corrosion assessment methods that have remained largely unchanged for more than 25 years.

A pilot program has already demonstrated proof-of-concept under ISO 12944 corrosion boundary testing, providing early technical validation of the approach.

The software is being developed using a large historical dataset to train models that can deliver higher accuracy and greater consistency than manual assessment.

In addition to faster turnaround times, the AI approach enables the capture and reporting of large volumes of data points, allowing for more comprehensive statistical analysis than a single manual measurement.

Modernising Coatings Performance Assessment

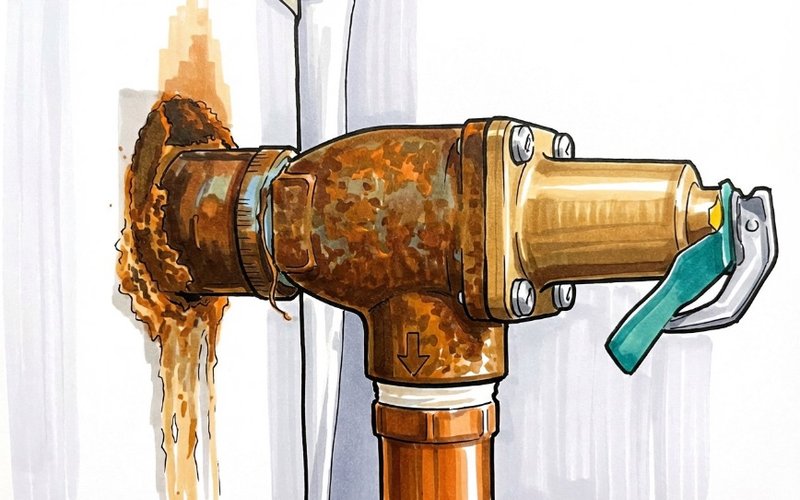

Protective coatings testing commonly relies on scribe-based methods that deliberately damage coatings to accelerate corrosion and assess performance by measuring corrosion creep from the scribe.

Current assessment techniques depend on subjective human judgement and manual measurement, making the process labour-intensive, time-consuming, and variable between operators.

Sparc and AIML’s software is being designed to replace this process with visually trained AI models capable of automatically detecting corrosion boundaries and coating disbondment.

The company estimates the AI-based workflow can reduce assessment time from around 40 minutes per result to tens of seconds.

Commercial Opportunity and Industry Support

Sparc estimates an addressable market of approximately 850 laboratories globally across the coatings industry, testing, and research organisations, with end-users conducting relevant performance assessments.

The company has received letters of support from multiple coatings industry participants, reflecting early interest in the commercial application of the technology.

It intends to pursue a commercialisation pathway based on industry co-development and future software licensing to established testing laboratories and coatings companies.

Beta testing in third-party laboratories is targeted within 12 months.

Innovation Focus Alignment

Managing director Nick O’Loughlin said the partnership aligns with Sparc’s focus on innovation within the protective coatings sector.

“This collaboration with the Australian Institute of Machine Learning at Adelaide University leverages complementary skills from both teams to develop AI-based software for the protective coatings industry,” Mr O’Loughlin said.

“It has the potential to significantly improve and accelerate R&D under testing methods which have been unchanged for more than 25 years.”

“The replacement of outdated manual corrosion assessment with computer vision has the potential to increase efficiencies and improve outcomes for the coatings industry,” AIML director Professor Simon Lucey added.