Peninsula Energy (ASX: PEN) and wholly-owned subsidiary Strata Energy have commenced the acidification process at Header House 16 under a production reset plan for mine unit 4 (MU-4) within the mothballed Lance uranium project in the US.

The company said the rate of acidity reduction was tracking ahead of schedule, with levels currently at 3.48 standard units (or less than half of the 8.5 SU natural acidity level at the start of acidification) and progressing well to the targeted mining level of less than 2.0 SU.

Once the process is complete, Peninsula expects the start of the leaching phase to provide it with a better understanding of MU-4 grade and recovery curves.

This will be instrumental in defining the medium and longer-term development profile for the project.

Five-Year Project Hiatus

Lance – one of the largest independent uranium projects in the US – was closed in 2019 due to low commodity prices and lower-than-expected recovery rates.

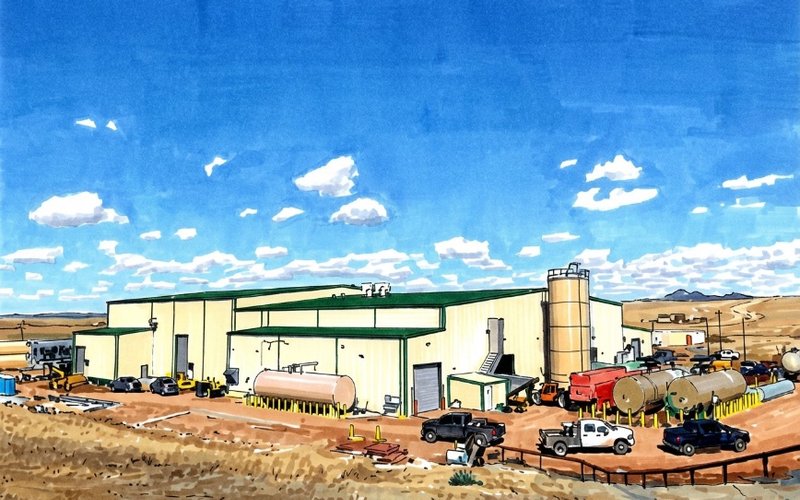

After five years on haitus, Peninsula commenced work to bring the project back online, resetting it from an alkaline-based in-situ recovery (ISR) operation to a low-pH (acidic) ISR development and establishing Peninsula as a fully-independent end-to-end producer of yellowcake.

MU-4 comprises six header houses and is forecast to account for approximately 60% of Peninsula’s forecast uranium production for 2026 and 2027 under the reset plan.

“While the team remains focused on addressing the legacy issues within MU-3 – stemming largely from the unexpected issues that halted acidification in the June 2025 quarter – overall the Lance project remains on track to deliver our CY2026 production guidance of 0.4 million pounds to 0.5Mlbs of yellowcake,” chief executive officer George Bauk said.

“The strong progress being made in MU-4, which is a key driver of the Company’s near-term production outlook, supports our expectation that production volumes will steadily increase from the March 2026 Quarter onwards.”

Performing Above Expectations

Acidification at Header House 14 commenced in December and will continue until March, after which the uranium-bearing solution will be redirected to the project’s central processing plant (CPP).

The process is currently performing above expectations, with flow rates averaging approximately 15 gallons per minute and exceeding the reset plan assumption of 12Gpm.

Flow rate performance to date at MU-4 has also been significantly higher than that achieved at MU-3 and is generally consistent with flow rates at MU-1 and MU-2 during previous alkaline-based in-situ recovery operations between 2015 and 2018.

The team is currently finalising […] Header House 15, and we have a clear schedule in place to complete all six header houses within MU-4 ahead of schedule,” Mr Bauk said.

Wellfield Design Review

A recent review of wellfield design patterns has seen Peninsula implement new maintenance plans and optimised pattern designs from MU-4 onwards.

Each header house will now consist of 30 production wells, with 18.2-metre spacings between production and injection wells (compared to 45 production wells and 24m spacings used in the development of MU-3)—a configuration intended to reduce the time required to reach the 2.0 SU target and speed up the flow of uranium-rich fluids to the CPP.

Peninsula confirmed that commissioning activities within the CPP are progressing well, with fine-tuning of multiple systems continuing as the elution, precipitation, filtration, and drying processes mature.

A key focus is the implementation of a purification system for process water, aimed at reducing impurity levels in the final dried yellowcake product.

Work has also commenced on replacing the corrosion-affected piping system in Phase 1 of the CPP, with installation of the new system due for completion this month, on schedule and below budget.