Altech finalises alumina plant designs to include lithium-ion capacity

Altech Chemicals (ASX: ATC) has settled on the designs of its proposed high purity alumina plant (HPA) in Malaysia to boost annual capacity to 4,500 tonnes per annum (tpa) and include HPA production for the burgeoning lithium-ion market.

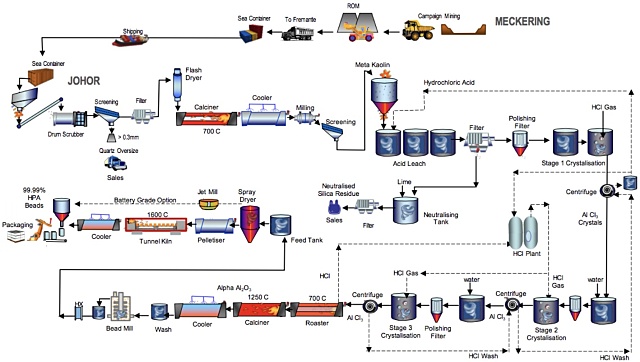

In the design upgrade, the plant process flow sheet now includes a flexible finished product line that allows HPA to be produced for both synthetic sapphire and lithium-ion battery industries.

With 5,000tpa in added capacity, up to 4,500tpa of HPA in 3mm-4mm amalgamated bead sizes can be produced for synthetic sapphire end users, while 1,500tpa in powder form has been included for lithium-ion manufacturers.

Altech published an updated bankable feasibility study in March 2016, which indicated the company could generate earnings before interest tax depreciation and amortisation in excess of US$55.7 million per annum once the processing plant has been completed.

This value is based on Altech receiving US$23.00 per kg of HPA.

Additionally, HPA will be produced from Altech’s own kaolin deposit in Western Australia and the company anticipates its productions costs will much lower than existing HPA producers.

Plant process flow diagram.

According to Persistence Market Research, the HPA market was worth US$1 billion in 2016 and this number is growing more than 16% annually.

Meanwhile, the lithium-ion battery sector is poised for “significant growth” due to the battery’s use in electric vehicles and green energy power storage. Electric vehicle manufactures use lithium-ion batteries with HPA coated cathode and anode electrode separator sheets to provide fire resistance.

Altech forecasts HPA consumption in the lithium-ion battery sector to surge from 1,000tpa in 2016 to 15,000tpa by 2025.

Synthetic sapphire is used to manufacture substrates for LED lights, semiconductor wafers for electronics and scratch-resistant glass in wrist-watch faces, optical windows, smartphones and other handheld devices.

The company aims to begin project development in 2018.