Additive manufacturing technology developer 3D Metalforge (ASX: 3MF) has achieved a new milestone and finished commissioning a range of customised polymer printers, paving the way for its expansion into the high-end polymer market for defence, maritime and oil and gas applications.

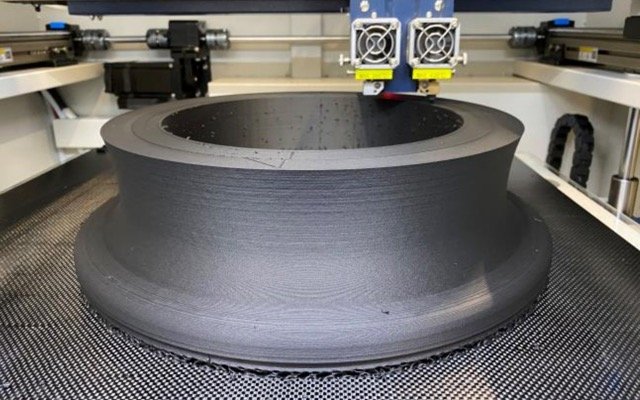

The company has now completed testing and commissioning a range of polymer printers, which have been customised for long-duration fully-dense prints.

These printers will expand 3D Metalforge’s offering into high performing polymers such as nylon carbon fibre (PACF) and polyether ether ketone (PEEK).

“We always ensure we have a wide range of materials available to help us meet client demand and we are very pleased to add these customised polymer printers to our range,” 3D Metalforge managing director Matthew Waterhouse said.

“We firmly believe there will be significant increased demand for high performing polymers as the additive manufacturing industry grows and matures,” he added.

3D Metalforge now has 33 polymer printers that are capable of printing up to 25 different materials.

Expanding into Australian mining

Today’s news follows 3D Metalforge penetrating the mining sector through an agreement with Intercast Australia earlier this month.

Over an initial 18-month period, Intercast will promote 3D Metalforge’s production and services to customers in Australia, including Mineral Resources (ASX: MIN), RCR Mining Technologies, Bradken, BGC and the Water Corporation.

As part of it, 3D Metalforge will provide sales, marketing and technical training to Intercast, which produces bronze and aluminium components for mining, excavating, quarrying, marine and general engineering industries.

Mr Waterhouse said the global pandemic had created supply chain challenges such as rising shipping costs and transport delays. As a result, he said companies were now looking for alternative solutions such as additive manufacturing.

“It also works alongside long-term sustainability targets that many companies are adopting, as additive manufacturing is able to reduce material waste by up to 90% and reduce inventory and storage costs,” he added.

3D Metalforge is also in preliminary discussions with other Australian companies which may consider additive manufacturing as an option to bypass supply chain problems.